What is extrusion blow Moulding machine?

What is an Extrusion Blow Molding Machine?

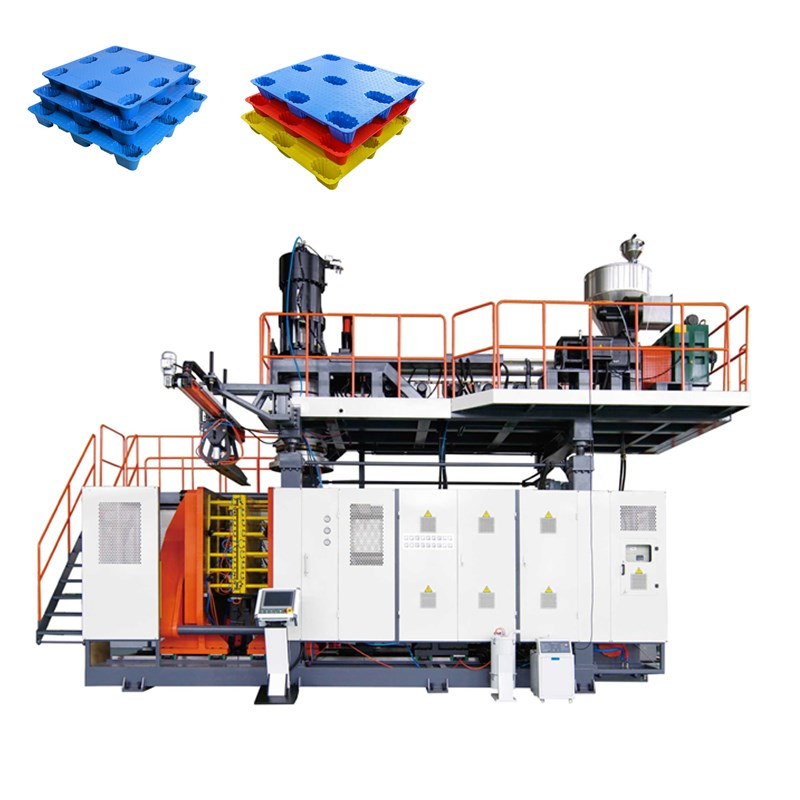

An extrusion blow molding machine is a type of manufacturing machine that can create hollow plastic products. These machines are used to create a variety of different products such as bottles, containers, and toys. Extrusion blow molding machines use melted plastic that is extruded through a die and then formed into a hollow shape using compressed air.

Advantages of Extrusion Blow Molding Machines

There are several benefits to using extrusion blow molding machines. One of the main advantages of jwell Blow molding machine is that they can produce large quantities of products quickly and efficiently. These machines are also very versatile and can be used to create products of different shapes and sizes. Additionally, the machinery is relatively easy to operate and maintain, which reduces production costs.

Innovation in Extrusion Blow Molding Machines

Recent advancements in technology have led to several major innovations in extrusion blow molding machines. These include the use of automation technologies, which have made the manufacturing process more streamlined and efficient. Another innovation is the ability to use more eco-friendly and sustainable plastics in the production process.

Safety Considerations

Safety is always a top priority when using extrusion blow molding machines. Operators of these machines need to be properly trained and follow all safety protocols to prevent accidents and injuries. Additionally, the machinery itself must be designed and manufactured to meet strict safety standards.

How to Use an Extrusion Blow Molding Machine

Using an extrusion blow molding machine and plastic blow molding equipment requires careful set up, operation, and maintenance. Proper set up involves configuring the machine to produce the desired shape, size, and material of the final product. During operation, care must be taken to ensure that the melted plastic is properly extruded and formed into the desired shape. Finally, regular maintenance is critical to ensure that the machine continues to operate properly and produce high-quality products.

Service and Quality

When it comes to extrusion blow molding machines, service is an important consideration. Manufacturers must provide excellent after-sales service and support to ensure that customers are satisfied with their purchase. Additionally, quality is crucial when using these machines. Manufacturers must maintain strict quality control measures to ensure that the products produced meet the necessary requirements and specifications.

Applications of Extrusion Blow Molding Machines

Extrusion blow molding machines are used to create a wide range of products for various industries. Some of the most common applications include packaging for food and beverages, personal care products, and industrial products. These machines are also used to create toys, sporting goods, and other consumer products.

In conclusion, extrusion blow moulding are an essential tool for manufacturers looking to create high-quality plastic products. These machines offer several advantages, including the ability to produce large quantities of products quickly and efficiently, their versatility in creating different shapes and sizes, and the relatively low cost of operation. However, safety, quality, and service are critical considerations when using these machines. With proper training, maintenance, and support, manufacturers can use extrusion blow molding machines to create quality products for a variety of industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Game

- Computer