What is the cost of DWC pipe extrusion machine

DWC Pipe Extrusion Machine - Cost and Benefits

Then investing in a DWC pipe extrusion machine will probably be your most useful bet if you are looking for a cost-effective solution for producing top-quality Double-wall Corrugated (DWC) pipes. We are going to explore the cost of DWC pipe extrusion machine and analyze its often advantages, various innovations, safety features, uses, application, and service statistics. So, let's dive to the international globe of DWC pipe extrusion machinery.

Cost

The fee of dwc pipe machine may vary with regards to the manufacturer, model, and specifications that are technical. Nonetheless, you will see affordable choices from $50,000 for elementary school machines to models that are higher-end can cost up to $150,000 for middle school machines. While the initial investment seem substantial, a DWC pipe extrusion machine's long-term benefits can be worth considering.

Advantages

The advantages of DWC pipe extrusion machines are plenty. These machines can somewhat reduce labor costs, increase production efficiency, and deliver constant quality. By having a DWC pipe extrusion machine, you can customize the pipe's size, thickness, color, and material according to your clients' demands. This versatility helps it be a manufacturers solution that are ideal suppliers coping with numerous kinds of customers.

Innovation

DWC pipe extrusion machines are continuously evolving with new innovations being technological enhance the manufacturing process further. For example, you will get models that are advanced level integrated automation that assist the equipment to adjust the extrusion speed, temperature, cooling, and pressure settings automatically. Some devices also feature stress sensors, leak detection systems, and automated screw barrel cleaning systems, ensuring a hygienic and manufacturing safe environment.

Safety

Ensuring the safety of workers and the environmental surroundings is critical in just about any manufacturing industry. DWC pipe extrusion machines were created with several safety features to avoid accidents and hazards. These safety features consist of Emergency Stop Buttons, safety interlocks for guarding, protective barriers, and alarms. By using these features, DWC pipe extrusion machines minimize the chance of damage and injury to the product and areas being surrounding.

Use

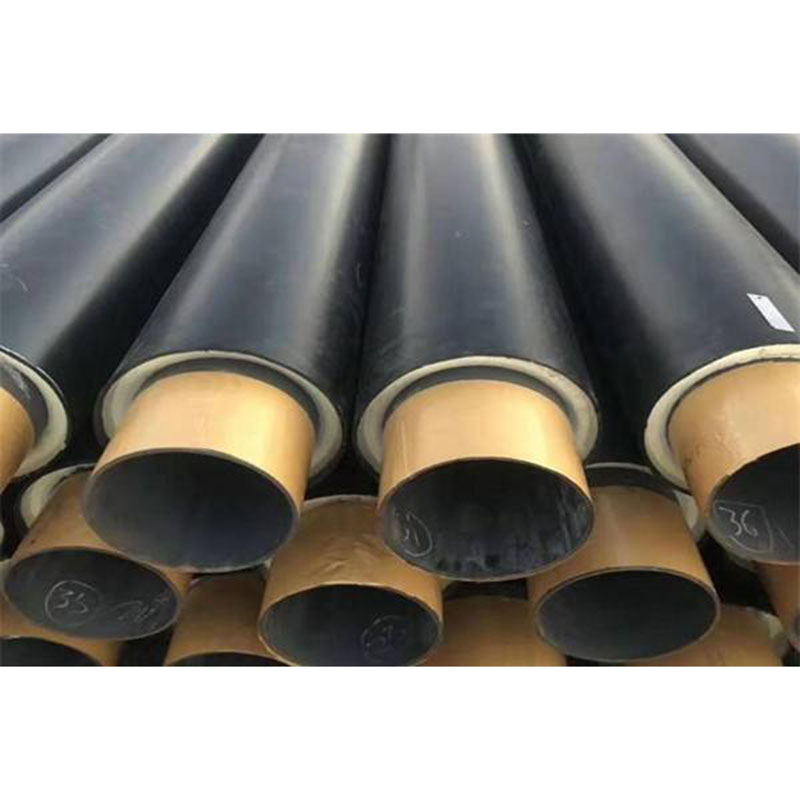

The application of DWC pipelines extrusion machine is vast, and the demand for it is ever-increasing. DWC pipelines are widely used in applications that want high energy, durability, and corrosion opposition. Some of the applications that are common drainage systems, sewerage systems, sewage treatment plants, electric and telecommunication cables protection, gas distribution systems, and commercial piping. DWC pipe extrusion machines enable their users to manufacture DWC pipes of diverse sizes and types, catering to the requirements of different companies.

How to use

DWC pipe extrusion machines are easy to operate and require minimal abilities. The equipment comes with an operating manual that outlines the step by step guidelines on how to use it. Most extrusion machines run using electricity, therefore guarantee it on that you have an adequate power turning. You need to feed the raw material to the extruder, where it gets melted and extruded through the die into the proper corrugated execution. The cooling and systems that are sizing form this final product which you can cut into necessary lengths.

Service

When purchasing a DWC pipe extrusion machine, it is crucial to look for a reliable and supplier/credible manufacturer provides excellent service support. A great manufacturer should provide prompt installation, commissioning, and training services to help you set the machine up and train you with its procedure. They need to also provide after-sales support, such as upkeep services, spare components supply, and technical assistance. Choosing the right manufacturer that the machine performs efficiently and delivers quality services and products.

Quality

Manufacturing quality DWC pipes extrusion device is crucial to match the customers' demands and industry standards. DWC pipe extrusion machines are designed to deliver consistent quality, clear of defects and deformations. The device's design, raw material quality, extrusion parameters, and cooling and sizing systems all contribute to producing high-quality DWC pipelines. To ensure it, and provide the right environment for manufacturing that you deliver quality services and products, continually monitor the equipment's performance, regularly maintain.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Παιχνίδι

- Computer