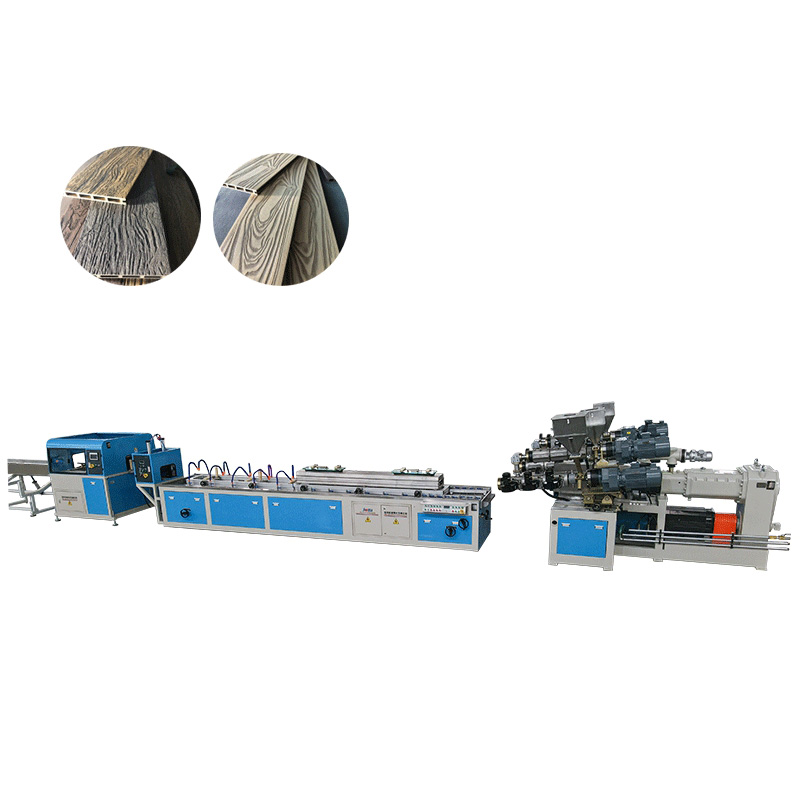

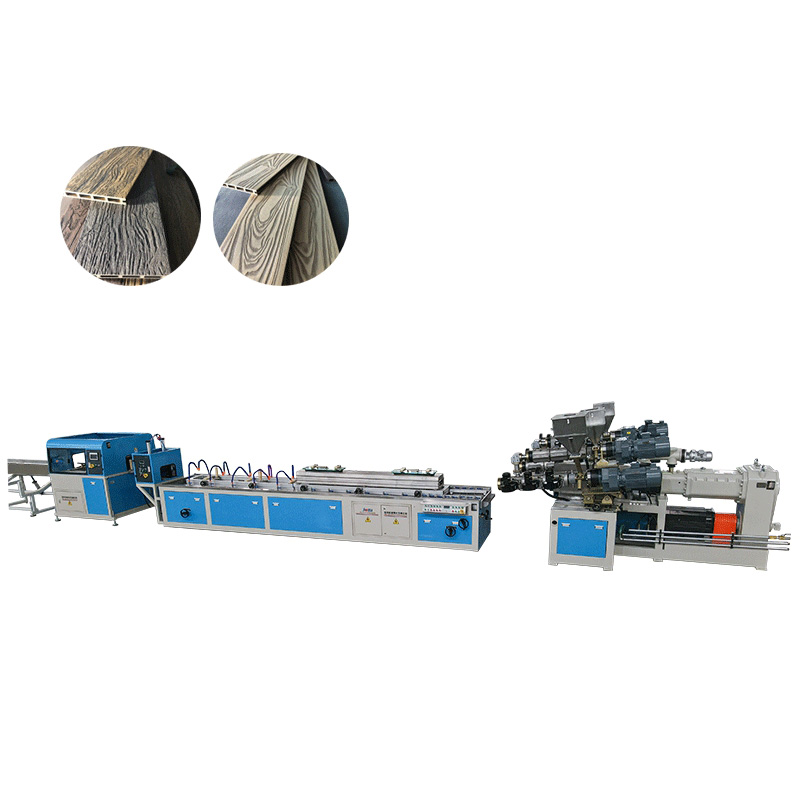

What does a pelletizing machine do?

A machine that is pelletizing a bit of equipment used to create small pellets or granules from raw materials such as for instance wood, hay, or also plastic. It works by compressing and shaping the materials into the desired shape and size, making them easier to manage and transport.

Great things about Pelletizing Machines

One of the primary great things about using a pelletizing plastic machine is them more compact so it can reduce the size of materials, making. This helps it be easier to store and transport them. Additionally increases their rack life, reducing the risk of decay or spoilage.

Another advantage is the undeniable fact that material that is pelletized frequently more uniform in size and shape, making it more effective to make utilization of in manufacturing or other companies. This can lead to cost savings and increased productivity.

Innovation in Pelletizing Machines

Current innovations in pelletizing equipment machines are making them more versatile and efficient. For instance, some machines can now pelletize a wider range of materials, including waste materials and byproducts such as for instance for example sawdust or residue that is agricultural.

Other innovations consist of improvements in automation, which make it easier to run and control the machines, as well as enhancements in safety features, which assist in preventing accidents and injuries.

Safety in Using Pelletizing Machines

Pelletizing machines can be dangerous if you do not used precisely. Some safety tips to keep in mind include wearing gear that is protective such as gloves and goggles, when running the machine. It is also important to follow the manufacturer's guidelines for use and not to overload the machine with too material this is certainly a lot.

The machine also needs to be regularly maintained and examined to make sure that it really is in good shape this is certainly working that all safety features are operating correctly. This can assist in preventing accidents and injuries.

Exactly how to Use a Pelletizing Machine

Using a machine this is certainly pelletizing relatively straightforward. First, the material that is raw loaded into the machine, where it really is compressed and shaped into small pellets or granules. The pellets are then released from the machine and can be kept, transported, or used for different purposes.

It is important to follow the manufacturer's instructions for usage and to keep the machine precisely to ensure its longevity and effectiveness.

Service and Quality

When choosing a film pelletizing machine it is important to consider both service and quality. Look for a machine which comes with good customer care and service that is after-sales. This can assist make sure that any presssing issues or problems that arise can be quickly resolved.

In regards to quality, look for a machine that is made from durable materials and has safety that is well-designed. It is usually important to select a machine this is certainly appropriate with the type of material you're going to be using.

Applications of Pelletizing Machines

Pelletizing machines can be used in a variety of companies, including manufacturing, agriculture, and waste management. They truly are commonly used to produce pellets from wood, hay, straw, and other materials that can be used for animal or gas bedding.

Pelletized plastic can be used in different procedures which can be manufacturing such as for example for instance injection molding or blow molding. Other companies which use pelletizing machines consist of textiles, pharmaceuticals, and food processing.

Pelletizing machines are a versatile and way that is efficient create small pellets or granules from raw materials. They feature numerous benefits, including increased efficiency, improved safety, and cost savings. With the machine that's right proper upkeep, you can create high-quality pellets that meet your specific requirements and applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Joc

- Computer