Conductive Foam Market Opportunities and Growth Potential in Diverse Industrial Applications

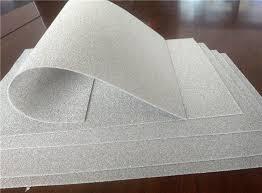

Conductive foam is a versatile material used primarily for electromagnetic interference (EMI) shielding, grounding, gasketing, and cushioning in electronic devices. Made of polyurethane, polyethylene, or other polymer bases coated with conductive metals like copper or nickel, conductive foam offers unique properties such as electrical conductivity, flexibility, and lightweight construction. As demand for advanced electronics and high-speed communication devices grows, the need for effective EMI shielding solutions is expanding rapidly.

Growing Demand in Electronics and Telecommunications

One of the most promising opportunities in the conductive foam market is its expanding role in the consumer electronics sector. Modern devices like smartphones, tablets, wearables, and laptops demand stringent EMI shielding to comply with regulatory standards and ensure performance. The proliferation of 5G networks is further driving demand for shielding materials to prevent signal interference and maintain device integrity. This trend creates significant opportunities for manufacturers to develop and supply conductive foam tailored for next-generation electronics.

Expansion in Automotive Electronics

The automotive industry represents another high-potential growth area. As vehicles incorporate more electronics—from infotainment systems to advanced driver assistance systems (ADAS) and electric vehicle (EV) battery management—EMI shielding becomes critical. Conductive foam is increasingly adopted to protect sensitive circuits from interference, ensure safety, and support reliable communication between components. Companies can seize this opportunity by developing automotive-grade conductive foam products that meet industry standards for heat resistance, durability, and performance.

Emerging Opportunities in Healthcare Devices

Healthcare electronics are also creating opportunities for conductive foam manufacturers. Medical imaging equipment, diagnostic devices, and wearable health monitors require effective EMI shielding to maintain accuracy and safety. With the rise of telemedicine and remote patient monitoring, demand for portable, reliable, and interference-free devices is increasing. Conductive foam suppliers can innovate by offering biocompatible, flexible, and high-performance shielding materials specifically designed for medical applications.

Growing Need in Industrial Automation

The push toward Industry 4.0 and smart manufacturing is driving demand for EMI shielding in factory automation systems, robotics, and industrial IoT devices. These interconnected systems are vulnerable to electromagnetic noise, which can disrupt operations or cause safety hazards. Conductive foam provides cost-effective and customizable EMI shielding solutions for control panels, enclosures, and sensor housings. Manufacturers who can deliver scalable, application-specific solutions have opportunities to capture market share in industrial automation.

Innovation in Materials and Manufacturing Processes

Another opportunity in the conductive foam market lies in the development of advanced materials and manufacturing techniques. Companies investing in research to create foams with improved conductivity, thermal stability, and environmental resistance can differentiate themselves. For example, eco-friendly or recyclable conductive foam options could appeal to industries prioritizing sustainability. Similarly, innovations in automated production processes can lower costs and increase consistency, making conductive foam more accessible for a wide range of applications.

Regional Market Opportunities

Regionally, the Asia-Pacific market offers substantial growth potential due to its dominance in electronics manufacturing and rapid adoption of 5G, EVs, and industrial automation. China, South Korea, Japan, and Taiwan are investing heavily in advanced electronics production, creating steady demand for EMI shielding materials. North America and Europe also offer opportunities driven by automotive electrification, telecommunications infrastructure expansion, and healthcare technology innovation. Companies that can establish strong local supply chains and customize solutions to meet regional requirements will be well-positioned for growth.

Strategic Collaborations and Customization

Finally, the trend toward customized solutions and strategic partnerships offers a valuable opportunity. Electronics OEMs increasingly demand application-specific shielding products. Conductive foam suppliers who collaborate closely with these OEMs can co-develop tailored solutions, build long-term relationships, and secure repeat business. Additionally, expanding distribution networks and forming alliances with raw material suppliers can strengthen market presence and improve supply chain resilience.

Conclusion

The conductive foam market offers diverse and compelling opportunities for growth across multiple industries, from consumer electronics and automotive to healthcare and industrial automation. Companies willing to invest in innovation, customization, sustainability, and strategic partnerships can capture these opportunities and achieve competitive advantages. As technology continues to advance and the need for effective EMI shielding grows, the market is poised for sustained expansion in the coming years.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Jeu

- Computer