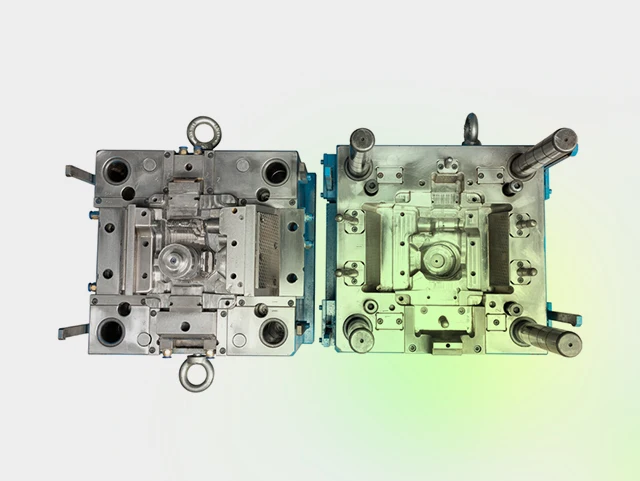

Automotive Precision: Plastic Injection Molds from GV Mold

GV Mold has established itself as a premier provider of plastic injection mold solutions tailored to the automotive industry. With a focus on precision, durability, and efficiency, GV Mold helps manufacturers produce high-quality components that meet the rigorous demands of modern vehicles. From under-the-hood parts to interior and exterior elements, GV Mold’s expertise ensures that every product enhances vehicle performance while maintaining aesthetic appeal.

The Role of Plastic Injection Molding in Automotive Manufacturing

Plastic injection molding is a cornerstone of automotive manufacturing, offering a reliable method for producing lightweight, custom plastic injection mold durable components at scale. The process involves injecting molten plastic into a precisely engineered mold to create parts with consistent quality and intricate designs. GV Mold leverages this technology to produce components that meet stringent safety standards while reducing production costs. By replacing traditional metal parts with injection-molded plastics, manufacturers can achieve improved fuel efficiency and lower vehicle weight without compromising strength or functionality.

Tailored Solutions for Automotive Applications

GV Mold specializes in creating custom molds designed specifically for automotive applications. Their engineering team works closely with clients to understand the unique requirements of each project, whether it involves under-the-hood components, exterior panels, or interior fixtures. For example, GV Mold designs molds for parts like cylinder head covers, bumpers, dashboards, and air vents, ensuring that each component seamlessly integrates into the vehicle’s overall design. This tailored approach allows automotive manufacturers to achieve superior performance and reliability across all vehicle systems.

Material Expertise for Automotive Components

Selecting the right material is critical in automotive manufacturing, where durability and safety are paramount. GV Mold offers extensive expertise in working with a wide range of polymers, including ABS, nylon, polypropylene, and polycarbonate. These materials are chosen based on their specific properties—such as heat resistance for engine components or flexibility for interior trims. By carefully evaluating material options, GV Mold ensures that each part meets its functional requirements while adhering to industry standards for safety and sustainability.

Advanced Manufacturing Techniques

GV Mold employs advanced manufacturing techniques to produce high-quality molds and components for the automotive industry. Their facilities are equipped with cutting-edge injection molding machines capable of handling complex geometries with tight tolerances. Technologies such as mold flow analysis optimize production processes by reducing defects and ensuring uniform cooling during molding. This commitment to innovation enables GV Mold to deliver consistent results while minimizing lead times and production costs for automotive manufacturers.

Quality Assurance for Automotive Standards

Quality assurance is integral to GV Mold’s operations, particularly in the automotive industry where precision and reliability are non-negotiable. The company implements rigorous inspection protocols at every stage of production, from initial design validation to final product testing. Using tools like 3D scanning and computerized measurement systems, GV Mold ensures that each component meets exact specifications and performs flawlessly in real-world conditions. This dedication to quality has earned them the trust of leading automotive manufacturers worldwide.

Sustainability in Automotive Manufacturing

As the automotive industry shifts toward sustainability, GV Mold integrates eco-friendly practices into its operations. The company focuses on reducing waste through efficient mold designs and recycling initiatives while exploring biodegradable or recycled materials for certain applications. These efforts align with the growing demand for greener manufacturing solutions in the automotive sector without compromising on quality or performance. By prioritizing sustainability, GV Mold helps clients meet their environmental goals while maintaining competitive advantages in the market.

Why Automotive Manufacturers Choose GV Mold

GV Mold’s comprehensive approach makes them a preferred partner for automotive manufacturers seeking reliable plastic injection molding solutions. Their ability to provide end-to-end services—from design consultation to full-scale production—ensures seamless execution at every stage of a project. By combining technical expertise with industry-specific knowledge, GV Mold delivers products that exceed expectations while helping clients achieve their production goals efficiently.

With its proven track record of excellence and commitment to innovation, GV Mold continues to lead the way in providing plastic injection mold solutions that empower automotive manufacturers to create durable, functional, and aesthetically pleasing vehicles for consumers worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Game

- Computer