Choosing the Right Workshop Equipment Provider in UAE: A Guide to Ironworker Machines

When it comes to metal fabrication and construction, having the right tools and equipment is key to achieving efficiency and precision. One of the most essential machines in any workshop is the ironworker machine—a powerful, all-in-one tool that simplifies metalworking tasks. If you're operating in the UAE, finding a reliable workshop equipment provider can make all the difference in streamlining your processes and ensuring high-quality results.

In this guide, we’ll explore why ironworker machines are a must-have, their benefits, and how to choose the best workshop equipment provider in the UAE.

What is an Ironworker Machine?

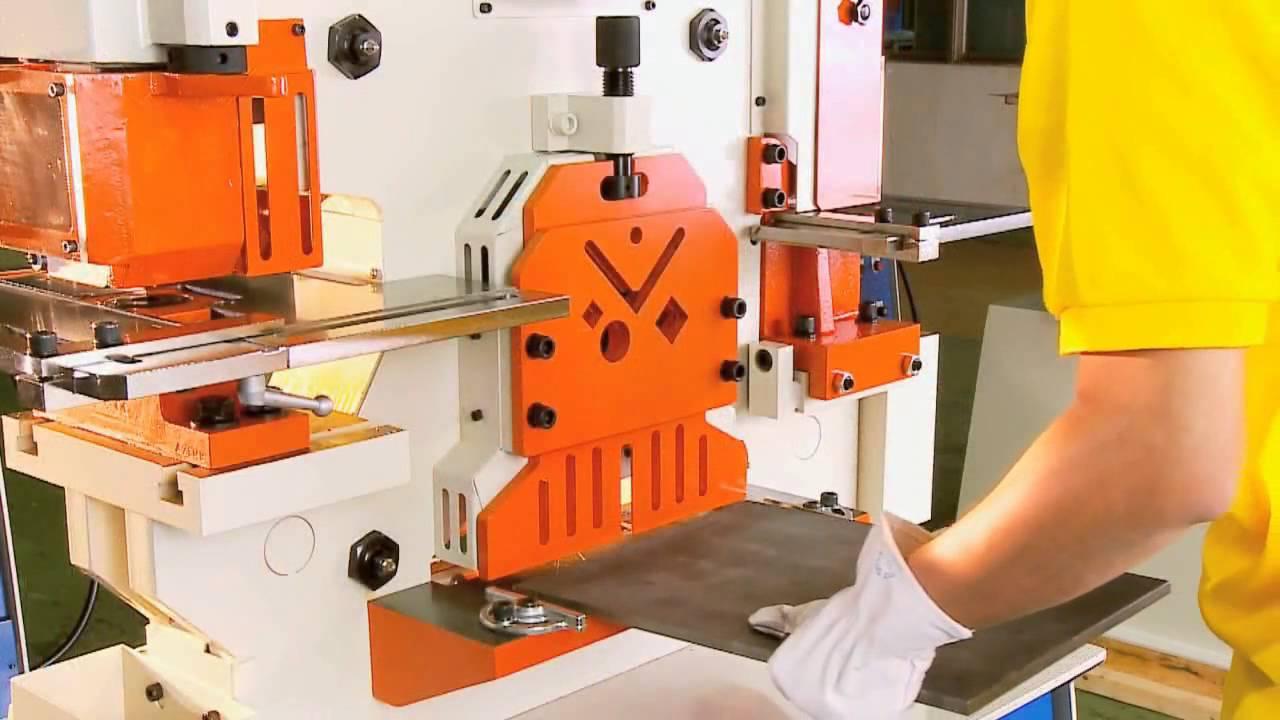

An ironworker machine is a multipurpose metalworking tool designed to handle several fabrication tasks, including punching, shearing, notching, and bending. This heavy-duty machine is widely used across industries such as construction, shipbuilding, and metal fabrication.

Ironworker machines are highly valued for their ability to cut through thick materials like steel and aluminum, making them an essential piece of equipment for workshops that require precision and speed.

Key Features of Ironworker Machines

What makes ironworker machines so useful is their ability to perform multiple tasks efficiently. Some key features include:

- Punching: Easily punches holes in steel plates and metal sheets with minimal effort.

- Shearing: Accurately cuts through flat bars, rods, and angle irons for clean, precise results.

- Notching: Helps create accurate notches in metal, which is crucial for assembling frames and structures.

- Bending: Forms metal into different shapes and angles without the need for additional machinery.

With these functions combined into one unit, ironworker machines help workshops save time, space, and operational costs.

Why Ironworker Machines are Essential in the UAE

The UAE is a booming hub for construction and industrial development, making ironworker machines an indispensable tool for metal fabrication businesses. Here’s why they are so valuable:

1. Improved Productivity

Ironworker machines eliminate the need for multiple machines, allowing workers to complete projects faster and with greater efficiency.

2. Cost Savings

Investing in a single ironworker machine means businesses can reduce expenses on separate cutting, punching, and bending machines.

3. High Precision

The machine delivers clean, accurate cuts and holes, ensuring that fabricated parts meet industry standards.

4. Space-Saving Design

Since one ironworker machine can perform multiple functions, it helps save valuable floor space in workshops.

5. Durability and Reliability

Built for heavy-duty industrial work, ironworker machines are known for their long lifespan and reliability, making them a smart investment for businesses in the UAE.

Choosing the Right Workshop Equipment Provider in UAE

Selecting a trusted workshop equipment provider in UAE is crucial when purchasing an ironworker machine. Here’s what to look for:

1. Quality of Equipment

Always choose a provider that offers durable, high-performance machinery from reputable brands. Quality equipment ensures longevity and better results.

2. Wide Range of Workshop Tools

A good supplier should have a variety of workshop tools and machines, including ironworker machines, hydraulic shears, and press brakes, allowing you to source everything in one place.

3. After-Sales Support

Look for providers that offer technical support, maintenance services, and spare parts availability to keep your machine running smoothly.

4. Customization Options

Some providers offer tailored equipment solutions to meet the specific needs of your business. Discuss your requirements and see if they can accommodate them.

5. Competitive Pricing

While quality should be your priority, choose a supplier that offers fair pricing and financing options to help manage costs effectively.

Why Ironworker Machines Are a Game-Changer for UAE Workshops

With rapid infrastructure growth in the UAE, workshops must stay competitive by increasing efficiency and maintaining high-quality standards. Ironworker machines provide:

- Faster production times, reducing delays in metal fabrication.

- A reduction in labor costs due to automation of key tasks.

- A seamless workflow by eliminating the need for multiple machines.

- Consistently high-quality results, ensuring customer satisfaction.

Whether you’re a small fabrication shop or a large-scale manufacturer, an ironworker machine will help you meet growing market demands.

How to Maintain an Ironworker Machine

To ensure longevity and peak performance, regular maintenance is key. Here are some simple tips:

- Keep it lubricated: Apply lubrication to moving parts to prevent wear and tear.

- Check for damage: Inspect the machine regularly for worn-out blades, punches, or dies.

- Clean the machine: Remove dust and metal debris to prevent blockages.

- Schedule professional servicing: Work with your equipment provider to get periodic maintenance and servicing.

Final Thoughts

Investing in an ironworker machine in UAE is a smart decision for any business looking to enhance productivity, reduce costs, and maintain precision in metal fabrication. However, choosing a reliable workshop equipment provider in UAE is equally important to ensure you get the best quality and long-term support.

By selecting the right provider and maintaining your machine properly, you can improve efficiency, take on larger projects, and stay ahead in the competitive UAE market. Whether you’re expanding your workshop or upgrading your equipment, an ironworker machine is a must-have tool that will elevate your operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- لعبة

- Computer