Diffractive Optical Elements Market Challenges: Tackling Supply Chain Disruptions and Material Constraints for Sustainable Development

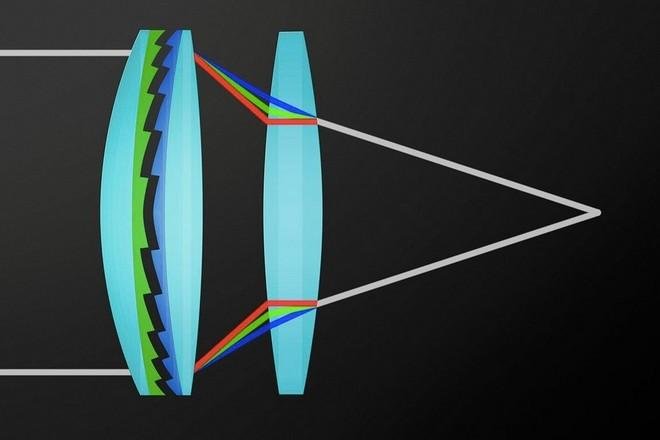

Diffractive Optical Elements (DOEs) are widely used in applications such as laser beam shaping, biomedical imaging, and industrial manufacturing. These components manipulate light through diffraction rather than refraction or reflection, offering unparalleled precision and efficiency. However, despite their advantages, the DOE market faces significant challenges that hinder its growth and broader adoption.

High Manufacturing Costs and Design ComplexitiesOne of the most pressing challenges in the Diffractive Optical Elements Market is the high cost of manufacturing. The production of DOEs requires advanced lithographic techniques, precise microfabrication, and high-grade materials, all of which contribute to elevated expenses. Small-scale production can be cost-prohibitive, limiting accessibility for startups and smaller enterprises.

Additionally, the design process of DOEs is complex, requiring extensive computational modeling and prototyping to achieve optimal performance. Even minor imperfections can significantly impact functionality, leading to high rejection rates and wasted resources. To address this challenge, investment in cost-effective fabrication techniques such as nanoimprint lithography and roll-to-roll processes could help reduce expenses and make DOEs more commercially viable.

Quality Control and Performance VariabilityEnsuring consistency in DOE performance is another major hurdle. Due to the intricate nature of diffractive optics, any slight deviation in the manufacturing process can lead to variations in optical efficiency, diffraction angles, and beam quality. This inconsistency makes it difficult for manufacturers to meet stringent industry standards, especially in high-precision fields like medical imaging and aerospace.

To mitigate this issue, companies need to implement automated inspection systems, AI-driven defect detection, and improved metrology techniques. By incorporating machine learning algorithms, manufacturers can predict defects and optimize production efficiency, thus enhancing overall product reliability.

Regulatory Barriers and Intellectual Property IssuesThe DOE market is subject to strict regulatory requirements, particularly in industries such as healthcare, defense, and telecommunications. Compliance with safety and performance regulations adds complexity to the development and approval processes, increasing time-to-market for new products.

Intellectual property (IP) concerns also pose a significant challenge, as the development of unique DOE designs requires extensive R&D efforts. Companies must navigate patent laws and licensing agreements to avoid legal disputes while protecting their proprietary technologies. Collaborative R&D partnerships and strategic licensing agreements can help firms leverage shared expertise while minimizing IP-related risks.

Technological Innovations and Market CompetitionWith rapid advancements in photonics and nanotechnology, the DOE market is becoming increasingly competitive. Companies must continuously innovate to stay ahead, incorporating new materials, hybrid optical solutions, and AI-driven design methodologies. However, smaller players may struggle to keep up with industry giants that have substantial R&D budgets and resources.

To remain competitive, businesses should focus on niche applications where DOEs offer distinct advantages, such as miniaturized optical sensors, augmented reality (AR) displays, and advanced microscopy. Furthermore, fostering collaborations with universities and research institutions can help companies access cutting-edge innovations without bearing the full cost of development.

Supply Chain Disruptions and Material ConstraintsGlobal supply chain disruptions, exacerbated by geopolitical tensions and economic uncertainties, pose another critical challenge for the DOE market. The availability of specialized materials, such as high-purity fused silica and advanced polymers, can fluctuate, leading to production delays and increased costs.

Diversifying supplier networks, investing in alternative materials, and adopting localized manufacturing strategies can help mitigate these risks. Additionally, companies should explore the potential of additive manufacturing (3D printing) for DOE production, which could reduce dependency on traditional supply chains and enable on-demand manufacturing.

Conclusion Despite the numerous challenges facing the Diffractive Optical Elements market, proactive strategies can help businesses navigate these obstacles. Investing in cost-effective manufacturing techniques, enhancing quality control, ensuring regulatory compliance, fostering technological innovation, and securing resilient supply chains are crucial for sustaining growth in this dynamic industry. By addressing these key issues, the DOE market can unlock new opportunities and expand its reach across various high-tech sectors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Game

- Computer