Which mechanical parts are made of steel pipe?

Which Mechanical Parts Are Made Out of Steel Pipe?

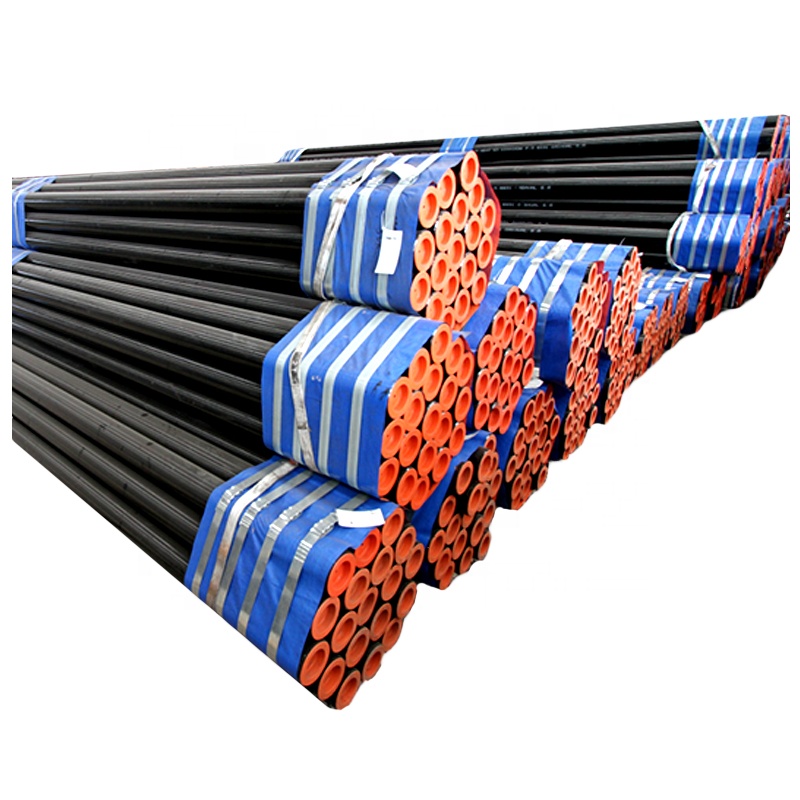

Whether you’re building a car or other mechanical project, steel pipe can be used for many purposes. It’s a strong, malleable material that can be custom-made to fit your needs.

Steel pipes are also recyclable and low-maintenance. This makes them a good choice for builders who want to minimize their impact on the environment.

Welded

The use of steel pipe for making mechanical parts and tubing has been around since the early 1800s. Today, it is used in a variety of applications and for the transportation of fluids, gas, powdered solids, thermal energy, and more. The material is also an economical choice for a wide range of projects.

There are several types of welded pipe, and they vary in price and quality. The most common type of welded pipe is electrical resistance welded (ERW) tube, which uses an automated process to create strong joints. Electric resistance welding is often a more cost-effective option than other types of welding because it allows for a larger number of welds in a shorter amount of time.

Other manufacturing methods include butt-welded pipe, skelp-seam welded pipe (SAW), and diaphragm welded pipe (DSAW). Each method has its advantages and disadvantages. For example, welded pipe has more uniform wall thickness than seamless steel pipe and is less susceptible to pitting and black spots that are common in seamless pipes. It is also easier to size welded pipe and has more versatility in the types of welds it can be made with.

SAW and DSAW pipe is produced from round plate that has been rolled, formed into a "U" or "O," and then welded to create a straight seam (SS) or a spiral seam (SW). It is primarily used for transport of steam, water, and gas lines steel reducer and is supplied according to ASTM Specifications A53 and A120 and API Specification 5L. It is available in sizes from 1/8 to 4 in. in diameter and is usually hot-dipped galvanized.

Welded pipe

Welded pipe is a more cost-effective option than seamless steel pipe and is available in a wide range of sizes and thicknesses. It is also more durable than seamless steel pipe because it is not affected by corrosion in water or gas environments.

Butt-welded pipe is manufactured from a rolled plate that has a more uniform wall thickness than seamless pipe. It is a cost-effective manufacturing process that is a good option for large production runs of small-diameter pipe that requires tight tolerances or thin walls.

Stainless steel welded pipe is also a popular product. This type of pipe has a wide range of applications in the oil and gas industry, as well as in the food service industry. It is also widely used for the manufacture of sanitary and industrial equipment, plumbing fixtures and appliances.

Another common application for stainless steel pipe is for the construction of highway bridges. This type of pipe is used to support the bridge deck and can reduce weight by up to 20 percent.

It is important to understand that the strength of a steel pipe depends on its tensile and yield strengths. The tensile strength is measured in pounds per square inch, while the yield strength is the minimum strength that the pipe can take before it breaks.

The tensile strength of the welded pipe is typically more than double that of the equivalent seamless steel pipe. This steel loop in box is because of the higher tensile strength that stainless steel can produce by heating and cooling it during the welding process. This is why welded pipe is sometimes referred to as a high-strength pipe.

Seamless

There are many mechanical parts that can be made out of steel pipe, such as oil drill pipes, automobile drive shafts, bicycle frames and steel scaffolding used in construction. They are made from solid tube billets that are perforated and rolled or spun to produce a mother tube that is then worked through hot and cold finishing processes to produce the required shape, dimensions and properties.

Some of the most common seamless mechanical parts are oil drill pipe, hydraulic cylinders, telescopic hoses and fuel lines. All of these parts can be made out of different types of steel pipe depending on the application and requirements.

Often, different organizations have various standards that determine how certain types of mechanical parts are made. It is important to be aware of these differences, so that you can properly describe your needs to the manufacturer.

In many situations, these specifications do not matter; however, there are a few instances where they do matter. For example, when a certain type of seamless mechanical pipe is being used to transport water, it should be tested for its strength and integrity.

If a certain type of seamless mechanical pipe is to be buried in soil, it should be tested for its durability and ability to resist deflection under ground pressure. It should also be tested for its resistance to corrosive gases and oxidation.

Important to be considered

Another factor that is important to be considered when choosing a seamless mechanical part is the wall thickness of the part. Typically, the thicker the wall of the pipe, the stronger it is. This is especially true of welded steel parts that are designed to be buried in soil.

This is due to the fact that a large amount of corrosive gases and oxidation can attack the surface of the pipe if it is too thin, and this will lead to corrosion. ThiS steel extension rings is why it is essential to choose a thicker, heavier walled pipe for applications that require high strength.

These thicker walls may also be necessary in some cases when a pipe is to be used to transport chemicals. It is also important to note that if a pipeline is destined to be transported under water, the thickness of the pipe will also be crucial for its safety.

Some of the most commonly available seamless mechanical parts are ERW (Electric Resistance Welded) pipe and stainless steel piping. Both of these types of pipes have different manufacturing methods and differ in terms of standards.

Stainless steel piping is an industrial material that is made from acid and heat resistant steel billets through heating, piercing, sizing and rolling. These pipes are mainly used in a variety of industries, such as petroleum, chemical, medical and food industries.

The piercing process involves piercing a hole in a solid round billet. Then, the pierced hollow tube is then elongated to decrease its thickness and finally, it is size reduced to the desired wall thickness.

These processes are very similar to those of ERW pipe, but the only difference is that a welded seam may be present in a welded pipe, while there will be no joints on the surface of a seamless pipe. The resulting pipe is usually completed to the wall thickness and dimensional specifications of the finished product.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Gioco

- Computer