Tailored Custom Mold Services: From Concept to Completion with Expertise

In the realm of manufacturing, tailored custom mold services are indispensable for companies aiming to achieve efficiency, quality, and innovation. From the initial concept to completion, these services provide a comprehensive approach to mold making that caters to the unique needs of each client.

Understanding Tailored Custom Mold Services

Tailored custom mold services encompass a wide range of activities, including design, prototyping, fabrication, and testing. This process begins with a collaborative effort between the client and the mold maker, where ideas are shared, and requirements are clearly defined.

The Design Phase: Collaborating for Success

A successful custom mold begins with a well-thought-out design. Skilled mold makers employ advanced software tools for Computer-Aided Design (CAD) to create detailed 3D models of the mold. This phase involves:

Client Consultation: Understanding the client's vision and objectives is crucial. This step helps mold makers gather critical information regarding the functionality, size, and aesthetics of the desired product.

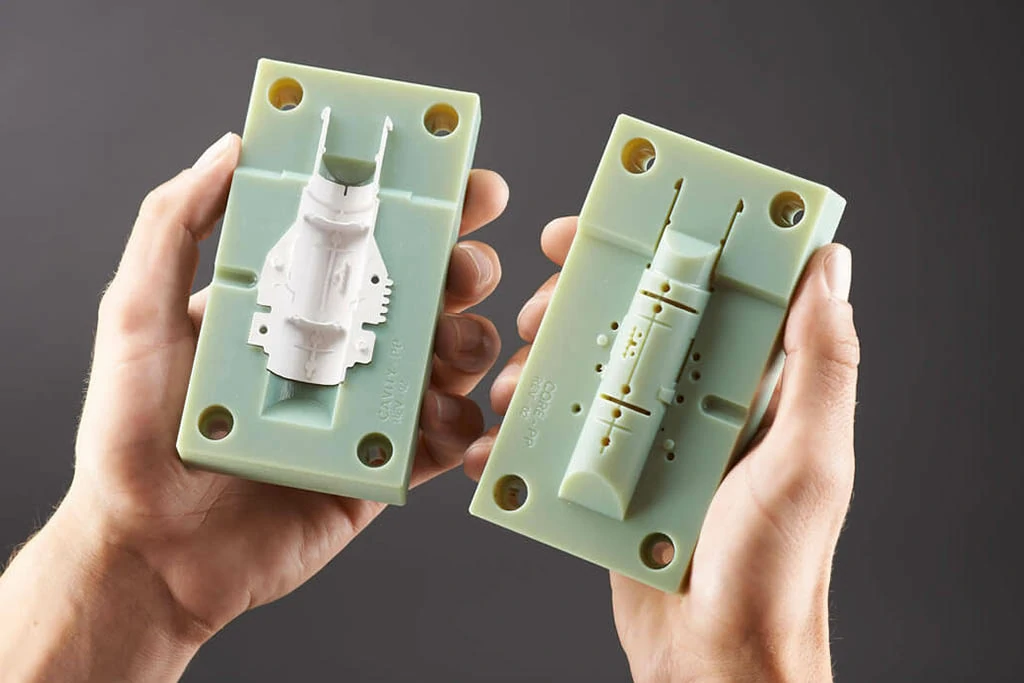

Prototyping: Once the design is finalized, a prototype is created. This allows both the client and the mold maker to visualize the end product and make necessary adjustments before moving on to the fabrication phase.

Material Selection: The choice of materials greatly influences the performance and longevity of the mold. Customized solutions often require specific materials that can withstand varying temperatures, pressures, and chemical exposures.

Fabrication: Turning Concepts into Reality

After the design and prototyping phases are successfully completed, the actual fabrication of the mold takes place. This stage is where the expertise of skilled mold makers shines.

Machining: Advanced machinery is used to carve out the mold from selected materials. Precision is key in this phase, as even minor discrepancies can lead to product defects.

Finishing: The finishing touches are applied to ensure the mold meets the required specifications, including surface treatment and polishing. This step is critical for molds intended for high-quality applications.

Testing and Quality Assurance

Quality assurance is an integral part of tailored custom mold services. Once the mold is fabricated, it undergoes rigorous testing to ensure it meets all design specifications. This may involve:

Trial Runs: Test runs using the mold are conducted to assess its performance. Any issues identified during this stage can be addressed before full-scale production begins.

Quality Checks: Mold makers implement strict quality control measures to ensure the mold consistently produces high-quality products. This includes dimensional checks, surface inspections, and functional tests.

Conclusion

Tailored custom mold services provide a holistic approach to mold making, offering clients the expertise needed to transform concepts into reality. From the initial design phase to the final quality checks, skilled mold makers play an essential role in ensuring that every mold produced meets the highest standards of quality and performance. As industries continue to demand more innovative and efficient solutions, tailored custom mold services will remain a cornerstone of successful manufacturing.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Game

- Computer