CAD and PLM Software Market Research | Comprehensive Market Analysis and Trends

CAD and PLM Software 2024

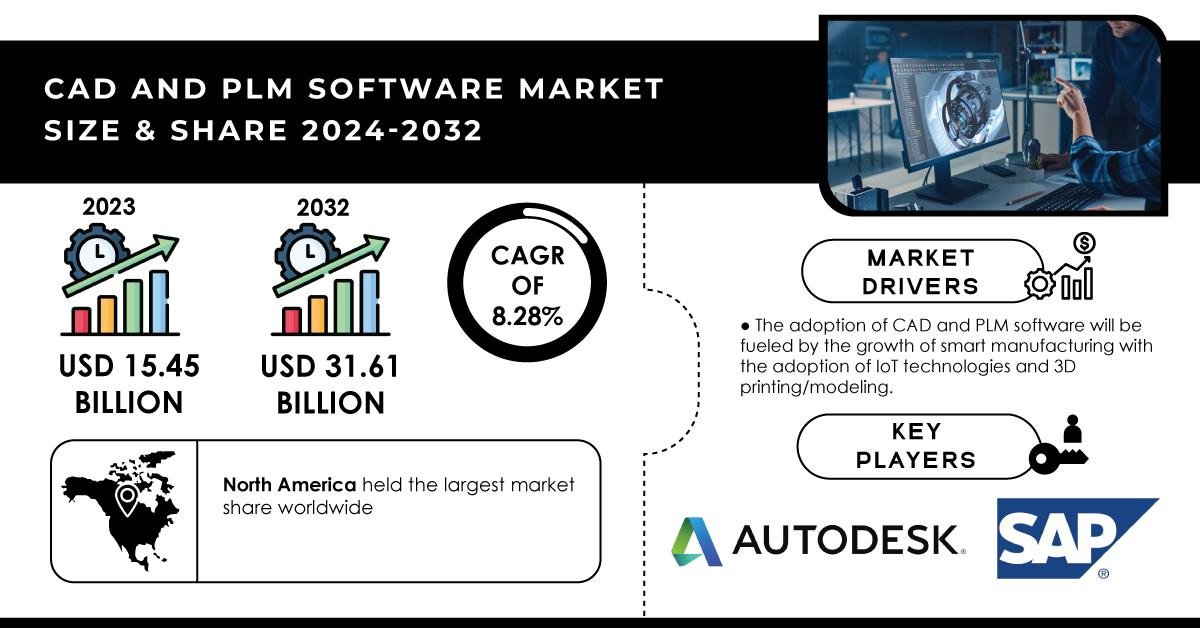

In today’s rapidly evolving manufacturing landscape, the importance of efficient product design and lifecycle management cannot be overstated. Computer-Aided Design (CAD) and Product Lifecycle Management (PLM) software have emerged as critical tools that enable businesses to streamline their design processes, enhance collaboration, and improve overall product quality. Together, CAD and PLM software not only facilitate the creation of detailed design specifications but also help manage every aspect of a product’s lifecycle from conception to disposal. As industries increasingly adopt these technologies, the CAD and PLM Software Market Share continues to grow significantly, with the market valued at USD 15.45 billion in 2023. It is projected to reach USD 31.61 billion by 2032, growing at a compound annual growth rate (CAGR) of 8.28% from 2024 to 2032. This upward trajectory reflects the growing recognition of the benefits these integrated solutions offer across various sectors.

Understanding CAD and PLM Software

CAD software allows engineers, architects, and designers to create precise drawings and models of products. It provides a platform for developing intricate designs, simulating product performance, and testing functionalities before physical production. With the advent of 3D modeling, CAD has revolutionized traditional design methods, enabling designers to visualize products in a three-dimensional space. This not only enhances creativity but also minimizes errors in the design phase, significantly reducing the time and costs associated with product development.

On the other hand, PLM software serves as a comprehensive framework for managing the entire lifecycle of a product. This includes planning, development, production, and eventual retirement of the product. PLM systems facilitate collaboration among various departments, ensuring that everyone from design to engineering, manufacturing, and marketing is aligned throughout the product lifecycle. By centralizing data and documentation, PLM software helps organizations maintain version control, comply with industry regulations, and enhance product quality.

The integration of CAD and PLM software brings together the strengths of both solutions, creating a synergistic effect that maximizes efficiency and innovation. Designers can seamlessly transition their CAD models into the PLM system, ensuring that all relevant information, such as materials, specifications, and design changes, is accessible to all stakeholders. This integration enhances visibility and communication throughout the organization, leading to informed decision-making and faster time-to-market.

Benefits of CAD and PLM Integration

The integration of CAD and PLM software offers numerous advantages that drive organizations to adopt these technologies. One of the most significant benefits is improved collaboration across teams. In traditional workflows, design changes could lead to miscommunication and delays, as different departments may not be aware of the latest updates. With integrated CAD and PLM systems, all teams have access to the most current information, reducing the likelihood of errors and fostering a more collaborative environment.

Another major advantage is enhanced data management. With the amount of data generated throughout a product’s lifecycle, managing this information effectively is crucial. Integrated CAD and PLM systems centralize data, allowing users to access documents, designs, and specifications from a single source. This eliminates the challenges associated with disparate systems and ensures that everyone is working with the most accurate and up-to-date information.

Moreover, the integration streamlines the change management process. In product development, changes are inevitable, and managing these changes efficiently is critical to maintaining timelines and budgets. Integrated CAD and PLM software allows organizations to implement change requests systematically. When a design modification is made, it can be immediately reflected in the PLM system, triggering necessary updates across relevant teams and documentation. This agility helps organizations adapt quickly to market demands and improves overall responsiveness.

Industry Applications

The application of CAD and PLM software spans a wide range of industries, each with its unique requirements and challenges. In the automotive industry, for instance, CAD software is used extensively to design complex components and systems. Integrating PLM ensures that all teams involved in the design, manufacturing, and testing phases are aligned, facilitating a streamlined workflow. As a result, automotive companies can enhance vehicle performance, improve safety features, and bring new models to market more quickly.

In the aerospace sector, where precision and compliance with stringent regulations are paramount, the integration of CAD and PLM systems is critical. Aerospace manufacturers rely on CAD to design intricate parts that must withstand extreme conditions. PLM software ensures that these designs meet regulatory standards and facilitates collaboration between engineering and manufacturing teams. This integration minimizes risks associated with compliance and enhances overall product quality.

The consumer electronics industry also benefits significantly from CAD and PLM software integration. Rapidly evolving consumer preferences require companies to innovate continuously. CAD enables the creation of cutting-edge designs, while PLM supports agile development processes, ensuring that products reach the market quickly. By leveraging integrated solutions, consumer electronics manufacturers can respond to trends and enhance customer satisfaction.

Challenges and Considerations

Despite the numerous benefits, organizations must also consider the challenges associated with implementing CAD and PLM software solutions. One of the primary challenges is the integration of these systems with existing workflows and software. Organizations often rely on a mix of legacy systems, and transitioning to a unified solution can be complex. Proper planning and change management strategies are essential to ensure a smooth transition.

Data security is another critical consideration. With centralized data storage, organizations must implement robust security measures to protect sensitive information from unauthorized access. Adhering to industry regulations and ensuring data compliance are also crucial aspects that organizations must address during the implementation process.

Additionally, the successful adoption of CAD and PLM software requires adequate training and support for employees. Users need to understand how to leverage the full capabilities of the integrated system to maximize its benefits. Organizations should invest in training programs to equip employees with the necessary skills to navigate the new tools effectively.

The Future of CAD and PLM Software

Looking ahead, the future of CAD and PLM software integration appears promising. The ongoing advancements in technology, such as artificial intelligence (AI) and machine learning (ML), are expected to enhance the capabilities of these solutions. For example, AI algorithms can analyze vast amounts of design data to identify patterns and suggest improvements, ultimately leading to more efficient design processes.

The rise of cloud-based solutions is also transforming the CAD and PLM landscape. Cloud technology enables real-time collaboration, allowing teams to work together from different locations seamlessly. As remote work becomes more prevalent, cloud-based CAD and PLM solutions will play a pivotal role in facilitating collaboration and improving productivity.

Furthermore, the increasing focus on sustainability and environmental considerations is driving the evolution of CAD and PLM software. Organizations are seeking ways to optimize resource usage, reduce waste, and minimize their carbon footprint. Integrated solutions will enable companies to assess the environmental impact of their designs and make informed decisions that align with sustainability goals.

Conclusion

In conclusion, the integration of CAD and PLM software is reshaping product development processes across various industries. By combining the strengths of these technologies, organizations can enhance collaboration, streamline workflows, and improve data management. As the CAD and PLM Software Market continues to grow, businesses that embrace these integrated solutions will be well-positioned to thrive in an increasingly competitive landscape.

As technology evolves, the future of CAD and PLM software looks bright. The incorporation of AI, cloud solutions, and a focus on sustainability will further enhance the capabilities of these systems. Organizations that invest in CAD and PLM integration will not only improve their product development processes but also drive innovation and create a competitive advantage in their respective markets. As the manufacturing landscape continues to change, embracing these advancements will be key to success in the years to come.

Contact Us:

Akash Anand – Head of Business Development & Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

About Us

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Read Our Other Reports:

Intelligent Document Processing Market Size

- CAD_and_PLM_Software_Market

- CAD_and_PLM_Software_Market_Size

- CAD_and_PLM_Software_Market_Share

- CAD_and_PLM_Software_Market_Growth

- CAD_and_PLM_Software_Market_Trends

- CAD_and_PLM_Software_Market_Report

- CAD_and_PLM_Software_Market_Analysis

- CAD_and_PLM_Software_Market_Forecast

- CAD_and_PLM_Software_Industry

- CAD_and_PLM_Software_Market_Research

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Spiel

- Computer