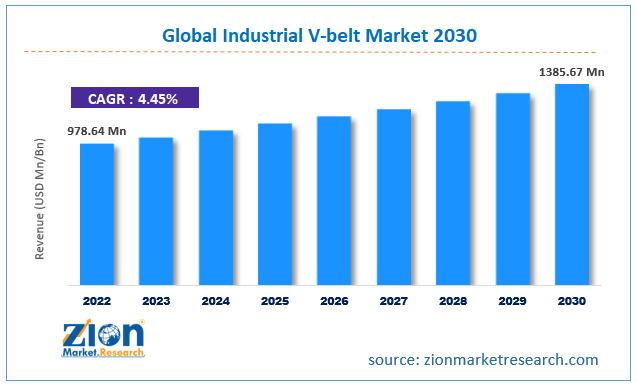

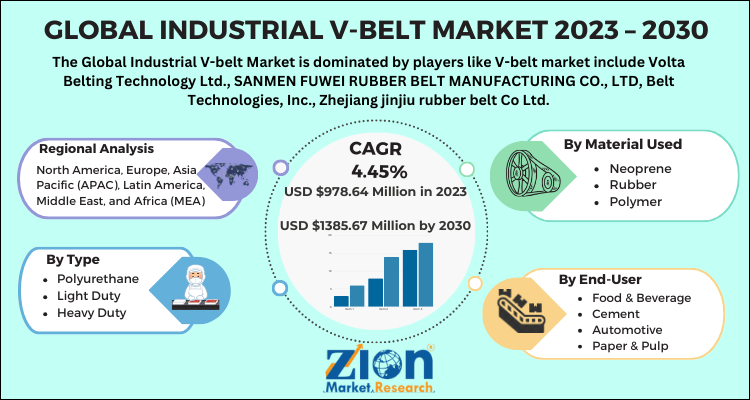

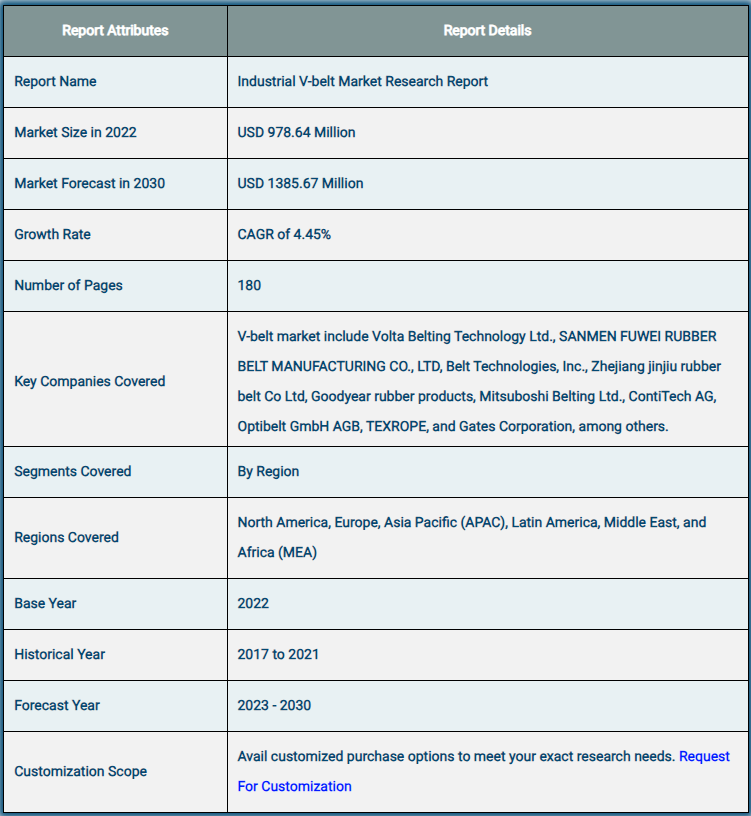

The worldwide industrial V-belt market is expected to grow from its estimated USD 978.64 million in 2024 to USD 1385.67 million by the end of 2032, according to a report released by Zion Market Research. Over the course of the projection period, the market is anticipated to rise at a CAGR of 4.45%. The growth factors, challenges, and effects on demand for the global Industrial V-belt Market are examined in this study for the period of forecasting. Additionally, it will support exploration and navigation of the emerging opportunities in the Industrial V-belt Market sector.

Introduction

The industrial V-belt market is a critical component of the broader power transmission industry. V-belts are widely used in various machinery and equipment across industries such as manufacturing, agriculture, mining, and automotive. This article explores the current trends, opportunities, and future prospects of the industrial V-belt market.

Market Overview

The industrial V-belt market has witnessed steady growth due to the increasing demand for efficient power transmission systems in various industrial applications. V-belts are preferred for their durability, flexibility, and ability to transmit significant power at high efficiencies. The drive belts used in power transmission are called V-belts. These belts’ main purpose is to transfer power from a main source, like a motor, to a secondary unit. V-belt provides the best possible mix of load distribution, traction, speed transfer, and longer life service. Often, polymer, fiber, or embedded fibers are used to create V-belts for added strength and reinforcement. With an increase in load, the belt’s V-form allows it to track in a groove on a sheave or pulley that has a similar shape, distributing torque and power.

Growth Factors for the Global Industrial V-Belt Market

Some of the factors driving the growth of the global industrial V-belt market are the automotive and metals & mining sectors’ increased demand for V-belts, advancements in engine belt technology, and the faster-growing industries in developing nations. V-belts are widely used in many industries since they are simple to install and come in a variety of diameters. Compared to a flat belt on the pulley, fast-moving belts are easier to maintain in the sheave grooves because of the V-shaped belt. In addition to having a longer lifespan of three to five years, V-belts can also achieve a high velocity ratio, provide compactness because of their tiny distance between pulley centers, and perhaps absorb shock when machines start up. Because of all these benefits, end users’ demand for industrial V-belts has grown significantly, which has fueled the expansion of the worldwide market. Additionally, the variables that may offer plenty of possibilities for the growth of the worldwide industrial V-belt market throughout the projected period include the automation sector’s expansion and the food and beverage sectors’ growing need. The expansion of the worldwide industrial V-belt market, nevertheless, can be constrained by the accessibility of V-belt alternatives.

The global Covid-19 pandemic has had a negative impact on economic growth in many nations. The governments of some nations imposed total lockdowns and travel restrictions in an effort to stop the disease’s spread. In the first and second quarters of 2020, the majority of industries, including automotive, food and beverage, metals and mining, and several others, were forced to halt operations. The need for V-belt dropped when these industries, which were the primary users of V-belt, discontinued operations. Raw materials are also no longer available as a result of the supply chain disruption. The production unit’s operations across all industries have also slowed down due to a labor shortage. In the context of COVID-19, all these factors have hindered the industrial V-belt market’s growth. But because lockdowns are becoming easier, industries are operating more quickly, which could help the market expand in the years to come.

Segmentation of the Global Industrial V-Belt Market

The type, material utilized, end-user, and region are the main classifications for the worldwide industrial V-belt market. The polyurethane, light duty, and heavy duty segments of the worldwide industrial V-belt market are separated based on type. The synthetic materials industry is divided into four categories based on the material used: neoprene, rubber, polymer, and urethane. Food & beverage, cement, automotive, paper & pulp, metals & mining, agricultural, and electricity & energy comprise the two halves of the application segment.

Market scope for industrial V-belts: report

International Industrial V-Belt Market: Geographic Perspective

Over the course of the forecast period, Asia Pacific is anticipated to provide the highest contribution to the worldwide industrial V-belt market. The market in this region is expanding due to reasons such the expansion of the automotive industries in China and India, the desire of key players to expand their operations in this region, and the growing demand for V-belts from the mining and food and beverage industries. North America is the market’s second-place finisher. North America’s engine belt market is expanding due to factors like the existence of major companies and steady advancements in engine technology. It is also expected that Europe would hold a sizable portion of the market.

Key Market Drivers

- Industrial Automation: The rise of automation in manufacturing and other industries is driving the demand for reliable and efficient V-belts.

- Agricultural Mechanization: The growing adoption of mechanized farming practices is boosting the need for robust V-belts in agricultural machinery.

- Mining and Construction: The expansion of mining and construction activities globally requires durable and high-performance V-belts.

- Automotive Industry: V-belts are essential in various automotive applications, contributing to market growth as the automotive industry continues to expand.

Challenges

- Raw Material Costs: Fluctuating prices of raw materials such as rubber and synthetic fibers can impact the production costs of V-belts.

- Market Competition: The presence of numerous manufacturers and suppliers increases competition, leading to price pressures.

- Technological Advancements: Continuous advancements in alternative power transmission systems pose a challenge to the traditional V-belt market.

Market Segmentation

The industrial V-belt market can be segmented based on product type, application, and region.

- By Product Type: Classical V-belts, narrow V-belts, wide V-belts, and others.

- By Application: Manufacturing, agriculture, mining, automotive, and others.

- By Region: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Regional Insights

- North America: The presence of a robust manufacturing sector and increasing automation drive the demand for V-belts.

- Europe: Technological advancements and the presence of leading automotive manufacturers contribute to market growth.

- Asia-Pacific: Rapid industrialization and growth in agricultural activities are key factors driving the market.

- Latin America and the Middle East & Africa: The expansion of mining and construction activities fuels the demand for V-belts in these regions.

Key Players

Several companies are leading the industrial V-belt market with their innovative products and extensive distribution networks. Notable players include:

- Continental AG: A global leader in V-belt manufacturing with a wide range of products.

- Gates Corporation: Known for its high-quality V-belts and advanced engineering solutions.

- Fenner PLC: Offers a diverse portfolio of power transmission products, including V-belts.

- Optibelt GmbH: Specializes in high-performance V-belts for various industrial applications.

Future Prospects

The future of the industrial V-belt market looks promising, with several factors contributing to its growth:

- Technological Innovation: Advancements in materials and manufacturing processes will enhance the performance and durability of V-belts.

- Sustainability: Increasing focus on sustainable and eco-friendly products will drive innovation in the V-belt industry.

- Emerging Markets: The growth of industrial activities in emerging markets will create new opportunities for V-belt manufacturers.

- Customized Solutions: The demand for customized and application-specific V-belts will increase, providing opportunities for market differentiation.

Conclusion

The industrial V-belt market is poised for steady growth, driven by increasing demand across various industries. While challenges such as raw material costs and market competition exist, continuous innovation and expanding industrial activities globally will ensure a positive outlook for the market. As industries continue to prioritize efficiency and reliability in power transmission, the importance of high-quality V-belts will remain significant.

Contact Us:

Zion Market Research212

USA/Canada Toll Free: 1 (855) 465–4651

Newark: 1 (302) 444–016611\

Web: https://www.zionmarketresearch.com/

Blog: https://zmrblog.com/

Browse other trend reports: