Leading Insert Molding Manufacturers: Excellence in Custom Molding Solutions

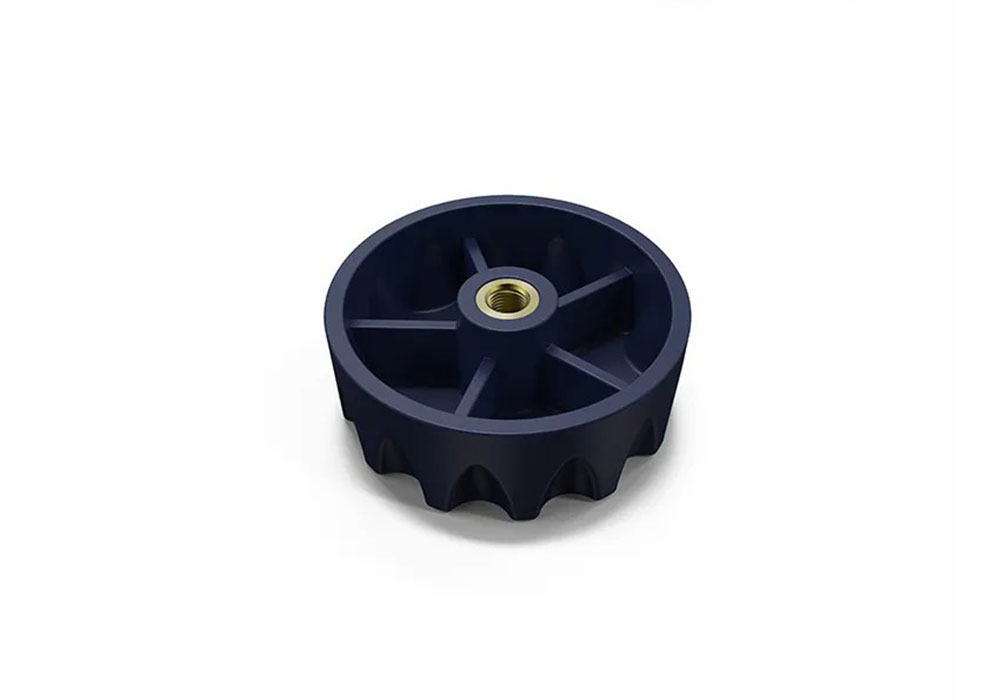

Insert molding is a versatile manufacturing process that involves inserting a pre-formed component into a mold cavity to create a final product. This technique is widely used across various industries to produce parts with enhanced strength, accuracy, and design flexibility. When it comes to precision insert molding services, choosing the right manufacturer is essential to ensure the highest quality and efficiency in the production process.

Custom Molding Solutions for Complex Challenges

Leading insert molding manufacturers stand out for their excellence in providing custom molding solutions tailored to meet the unique requirements of each project. These companies have extensive experience and expertise in working with a wide range of materials, components, and design specifications to deliver high-quality products that meet or exceed customer expectations.

Technical Expertise and Innovative Solutions

One key advantage of working with a reputable insert molding manufacturer is their ability to provide custom solutions for complex manufacturing challenges. Whether it's creating intricate designs, incorporating multiple components into a single part, or meeting strict dimensional tolerances, these manufacturers have the expertise and technical capabilities to deliver innovative and effective solutions.

Personalized Customer Service and Support

In addition to their technical prowess, leading insert molding manufacturers also excel in providing personalized customer service and support throughout the entire production process. From the initial design consultation to the final product delivery, these companies prioritize communication, collaboration, and transparency to ensure that the project meets all requirements and deadlines.

State-of-the-Art Equipment and Quality Control

Furthermore, top insert molding manufacturers invest in state-of-the-art equipment, technology, and quality control measures to maintain the highest standards of precision and consistency in their manufacturing processes. By utilizing advanced machinery and techniques, these companies can produce parts with tight tolerances, repeatable accuracy, and superior surface finishes.

Commitment to Continuous Improvement and Innovation

Another key strength of leading insert molding manufacturers is their commitment to continuous improvement and innovation. These companies actively engage in research and development efforts to explore new materials, processes, and technologies that can further enhance the performance, quality, and cost-effectiveness of their products.

Cost Savings and Efficiency Gains

Furthermore, working with a reputable insert molding manufacturer can also result in significant cost savings and efficiency gains for customers. By leveraging economies of scale, streamlined production processes, and optimized tooling strategies, these companies can deliver high-quality parts at competitive prices while minimizing lead times and production waste.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Gioco

- Computer