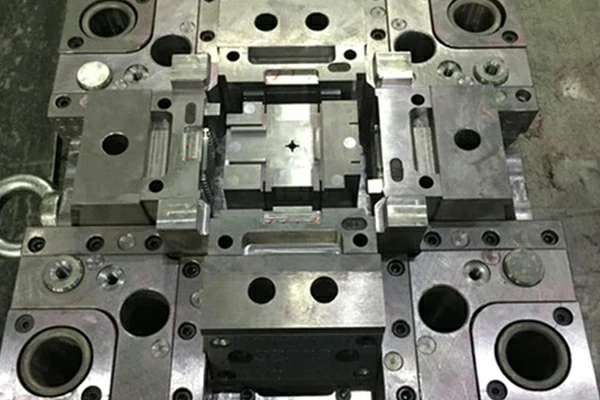

Precision Custom Injection Mold Solutions for Complex Manufacturing

Custom injection mold tooling offers efficient solutions for specialized projects that require precision and accuracy. When it comes to complex manufacturing processes, having the right tools is essential to ensure the quality and consistency of the end product.

Meeting Unique Project Needs

Precision custom injection mold solutions are designed to meet the unique needs of each project, whether it involves producing small, intricate parts or larger, more complex components. These custom molds are created using advanced technology and techniques that allow for precise control over the manufacturing process.

Benefits of Custom Injection Mold Tooling

One of the key benefits of custom injection mold tooling is the ability to create highly detailed and complex parts with tight tolerances. This is crucial for industries such as aerospace, automotive, and medical devices, where precision is paramount. By working closely with a team of experienced engineers and designers, companies can develop custom molds that meet their exact specifications and requirements.

Flexibility in Materials and Design

In addition to precision, custom injection mold tooling offers flexibility in terms of materials and design options. Whether you need a mold that can withstand high temperatures, corrosive chemicals, or extreme pressures, custom solutions can be tailored to suit your specific requirements. This allows manufacturers to produce a wide range of products with varying characteristics and properties.

Increased Efficiency and Productivity

Custom injection mold tooling also allows for faster production times and increased efficiency. By eliminating the need for multiple tool changes and adjustments, companies can streamline their manufacturing processes and reduce downtime. This results in cost savings and improved productivity, ultimately leading to a more competitive edge in the market.

Staying Ahead of the Competition

Furthermore, custom injection mold solutions can help companies stay ahead of the competition by enabling them to innovate and adapt to changing market demands. With the ability to quickly design and produce new molds for specialized projects, companies can capitalize on emerging trends and opportunities in their industry.

Conclusion

Overall, custom injection mold tooling offers a range of benefits for companies looking to optimize their manufacturing processes and achieve superior results. By incorporating precision, flexibility, efficiency, and innovation into their operations, companies can drive growth, improve quality, and stay ahead of the competition in today's fast-paced market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Politics

- IT

- Relationship

- Blockchain

- NFT

- Crypto

- Fintech

- Automobile

- Faith

- Family

- Animals

- Travel

- Pets

- Coding

- Comedy

- Movie

- Game

- Computer