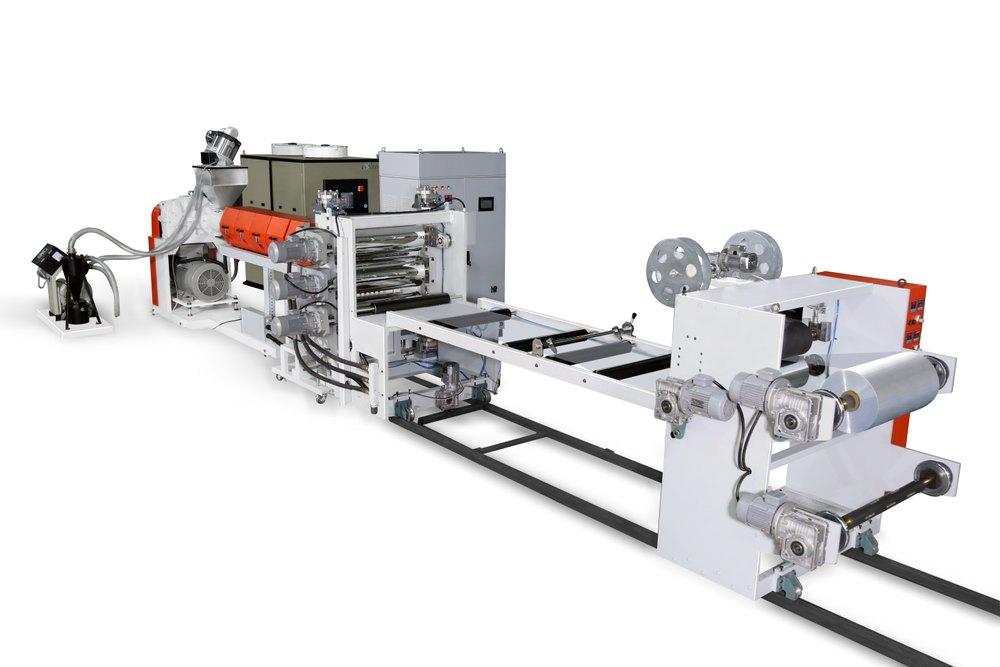

The Framework as well as Procedure of Sheet As well as Plate Extrusion Lines

A sheet as well as plate extrusion line is an equipment made use of to build plastic things. It's useful as compared to various other production procedures due to the fact that it can surely develop really intricate cross-sectional layouts as well as deal with breakable products.

The procedure starts with a obstruct of product that's heated up to the called for temperature level as well as moved into a chamber where a pass away is equipped. It's after that pressed with the pass away opening up as a lengthy remove of the preferred cross-section.

Framework

A sheet extrusion line normally includes an Extruder (solitary or double screw), geared up with a Display Changer as well as a Equipment Pump. It additionally consists of a Fixed Mixer (occasionally feeding a Coextrusion Feedblock that's come before by several added extruders collections) as well as a level sheet pass away with Film Extrusion Line.

The level sheet pass away is a warmed circulation chamber that obtains the evenly molten polymer at a main entryway as well as extrudes it with flexible pass away lips into a level leaving sheet of preferred density. The pass away lips might be by hand changed or immediately regulated by thermally increased/contracted screws or a density gauging as well as manage system.

The sheet is after that shared to a 3 (or more) roll pile to be cooled down in the past it's run off-line into winding or shearing tools. In most cases the sheets can surely be run straight into inline thermoforming systems. Thermoformers are made use of to build things such as plastic mugs as well as layers, automobile body components as well as roadside indicators as well as individual defense tools from plastic sheets.

Procedure

Sheet as well as plate extrusion lines are the tools made use of to warmth the plastic basic materials (fragments) in the extruder, thaw them, and afterwards extrude them into sheets with the mould. They are generally made use of in sore product packaging as well as plastic publishing sector.

They can surely generate different sort of plastic items, such as hollow plastic tubes as well as equipment components. These items can surely be designed in several means with the extrusion molding procedure.

The crucial benefit of this procedure is its capability to develop geometric go across areas that don't transform fit. This makes it an excellent selection for generating attractive trims, for instance.

PP, PS, PVC, EVA, as well as ABS plastics can surely all be extruded on a sheet or plate extrusion line. Depending upon the product's needs, it might be more refined by thermoforming or various other procedures.

image source https://www.pinterest.ph/

Upkeep

One of the most budget-friendly method to always keep your extrusion line of Sheet And Plate Extrusion Lines in excellent form is with a regimen upkeep program. This is a crucial part of your company's success as well as can surely avoid significant downtime as well as pricey repair services later on. It additionally conserves loan over time, as it enables your team to concentrate on more crucial jobs as opposed to managing technological concerns.

The greatest section is that a lot of extrusion line suppliers are greater than pleased to send out over a designer for your center to aid in this procedure. The designers will certainly have the ability to reveal you the ropes, in a manner of speaking, as well as offer you idea that will certainly make your manufacturing smoother as well as more effective. Furthermore, they'll aid you develop a budget plan strategy that benefit your business. It is the correct relocate for your company, as well as will certainly spend for itself sometimes over.

No matter the dimension of your company, it is constantly greatest to have actually a trustworthy as well as reliable extrusion line maker accessible. They'll have the ability to supply you with all the details you should make an educated choice concerning which equipment corrects for your demands, as well as they'll also have the ability to suggest upgrades or attachments that will certainly boost your procedure.

image source https://www.pinterest.ph/

Fixing

Sheet As well as Plate Extrusion Lines are an integral part of any type of 3D publishing procedure. Throughout the procedure of 3D publishing, a variety of concerns can surely take place that influence the efficiency of the printer as well as its capability to generate high quality outcomes.

Under-extrusion, which can surely result in layers not sticking with each other, bending or damaging down, is among one of the most usual issues that people deal with in their 3D publishing ventures. Under-extrusion can surely be brought on by a range of aspects as well as is typically very easy to detect the Profile Extrusion Lines Series.

1. Filament Grinding: This can surely be quickly found by the "clicking" audio that originates from the extruder equipments. This release is an outcome of the equipments clutching into the filament also securely which triggers it to use down as well as work away the plastic product within it.

2. Obstructed Nozzle: This can surely be an issue with the nozzle itself. It can surely be addressed with a couple of fast as well as straightforward treatments without the should dismantle the extruder head.