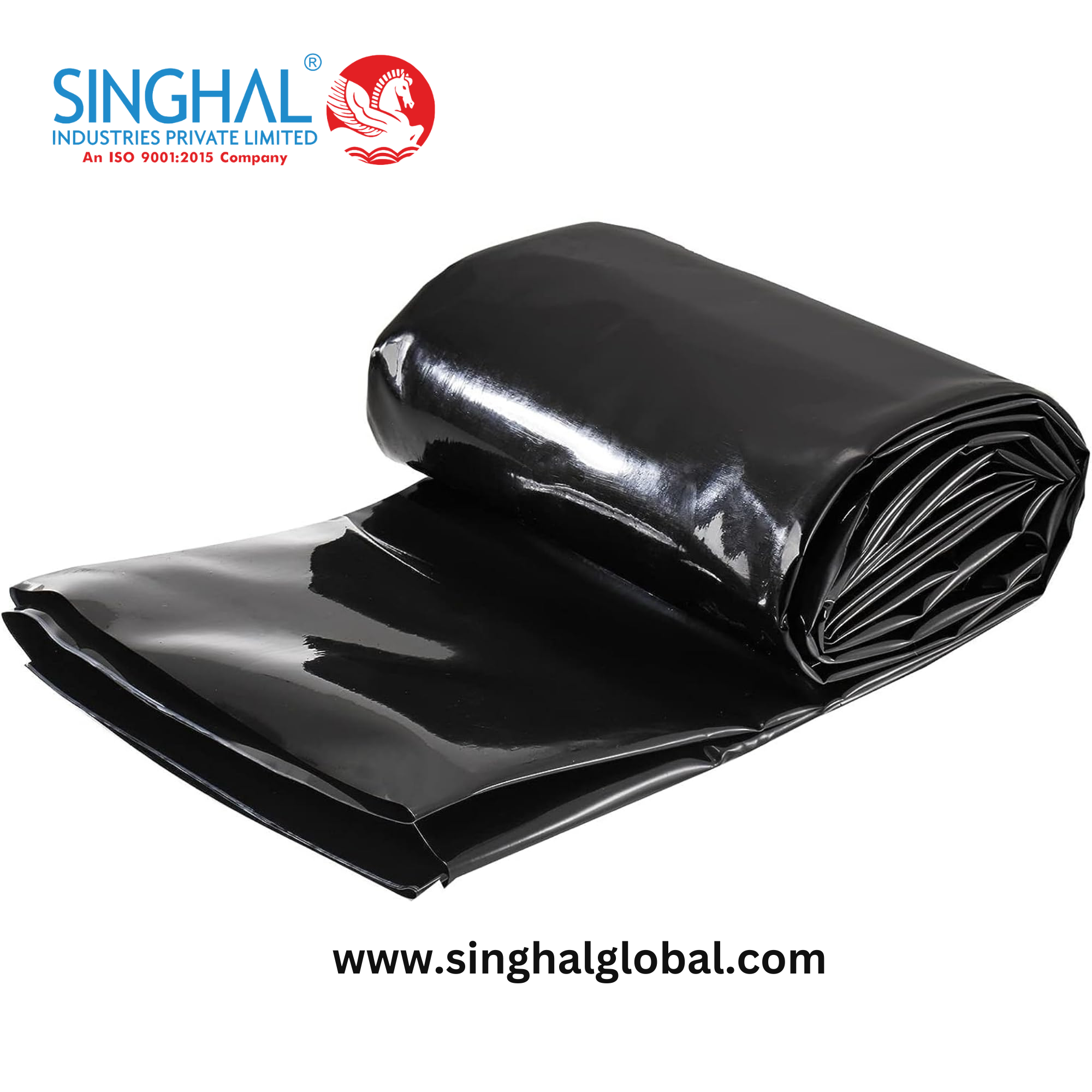

Geomembrane liners are the unsung heroes of our landfills and environmental containment projects. These massive sheets of high-tech plastic act as a barrier, preventing harmful Geomembrane sheet price in india escaping and protecting our precious environment. However, even the most resilient geomembrane can be susceptible to challenges during installation. Just like any construction project, meticulous planning and addressing potential issues upfront are key to a successful and secure installation.

Common Challenges and How to Conquer Them:

- Uneven Subgrade:

Imagine laying a sheet over a bumpy road – that's essentially what you're trying to avoid with geomembrane installation. An uneven subgrade, the underlying soil or base where the liner is placed, can cause punctures, tears, or stress points on the geomembrane.

- Solution: Thorough subgrade preparation is critical. This involves removing rocks, debris, and any sharp objects that could damage the liner. The subgrade should then be compacted and graded to achieve a smooth, level surface. In some cases, a protective layer of geotextile fabric can be used to provide additional cushioning and separation between the subgrade and the geomembrane.

- Weather Woes:

Mother Nature can throw a wrench into any construction project, and geomembrane installation is no exception. Extreme heat can cause the geomembrane to become brittle and HDPE geomembrane sheet manufacturers in india. Conversely, very cold temperatures can make the material stiff and difficult to handle. High winds can also pose a challenge, making it difficult to properly deploy and secure the geomembrane sheets.

- Solution: Scheduling installation during favorable weather conditions is ideal. However, this isn't always possible. If working in hot weather, consider using shade tents or starting work earlier in the day to avoid peak heat. In cold weather, using specialized equipment for handling and deploying stiffer geomembrane material might be necessary. For windy conditions, temporary windbreaks or postponing deployment until the wind subsides are sensible options.

- Seaming Shenanigans:

Geomembrane sheets are typically large and need to be seamed together to cover the entire containment area. Improper seaming can create weak points where leaks could occur. There are two main methods for seaming geomembrane liners – fusion welding and double-sided tape. Both methods require specialized equipment and trained personnel to ensure proper and secure seams.

- Solution: Invest in qualified installers with experience in geomembrane seaming techniques. Regular inspections and quality control measures throughout the seaming process are crucial. Non-destructive testing methods can be used to ensure the integrity of the seams.

- Storage and Handling Mishaps:

Geomembrane sheets are large and require careful handling during storage and deployment. Improper storage can expose the material to damaging ultraviolet (UV) rays, leading to degradation. Rough handling during deployment can also cause tears or punctures.

- Solution: Store geomembrane sheets in a cool, dark location away from direct sunlight. When handling the material, use proper lifting equipment and avoid dragging the sheets across rough surfaces. Following the manufacturer's recommendations for storage and handling is essential.

- Site Security Concerns:

Once installed, geomembrane liners need to be protected from vandalism or accidental damage during the construction phase or future maintenance activities.

- Solution: Implementing proper site security measures such as fencing and signage is crucial. Workers on the site should be informed about the location and importance of the geomembrane liner.

The Importance of a Qualified Installation Team

Overcoming these challenges requires a skilled and experienced installation team. Look for a team with a proven track record in geomembrane installation and a strong understanding of the specific challenges associated with your project. The team should have access to the necessary equipment and expertise for proper subgrade preparation, seaming techniques, and safe handling of the geomembrane material.

Conclusion: A Secure Foundation for Environmental Protection

Geomembrane liners play a vital role in safeguarding our environment from landfill leachate and HDPE geomembrane sheet price. By anticipating and addressing potential installation challenges, we can ensure these silent guardians function effectively for years to come. Remember, a well-installed geomembrane liner is an investment in a cleaner and healthier future.

Frequently Asked Questions (FAQs):

1. What makes Singhal Industries a qualified partner for geomembrane sheet installation?

Singhal Industries has extensive experience in geomembrane liner installations across various environmental containment projects. Our team of skilled and certified professionals understands the specific challenges associated with geomembrane deployment and possesses the expertise to overcome them. We utilize state-of-the-art equipment and stringent quality control measures to ensure a secure and long-lasting installation.

2. How can Singhal Industries help me address potential challenges during geomembrane sheet installation?

At Singhal Industries, we take a proactive approach to geomembrane installation. Our team conducts a thorough site assessment to identify potential subgrade issues and weather patterns. We offer recommendations for proper storage and handling practices to minimize the risk of damage. Additionally, our expert technicians are highly skilled in various seaming techniques, ensuring secure and reliable connections between geomembrane sheets.

3. Does Singhal Industries offer any additional services related to geomembrane sheet installation?

Singhal Industries goes beyond just installation. We provide a comprehensive suite of services to support your project from start to finish. This includes subgrade preparation, geotextile installation (if required), seaming with non-destructive testing, and final quality control inspections. We can also offer ongoing maintenance and repair services to ensure the continued effectiveness of your geomembrane liner system.