The Role of Lubricating Oil System in Roller Bits

Have you ever wondered how Roller Bits work? One associated with elements that are key make Roller Bits function effortlessly could be the lubricating oil system. We shall explore the value associated with lubricating oil system in Roller Bits and how it contributes to their success. Why don't we dive in.

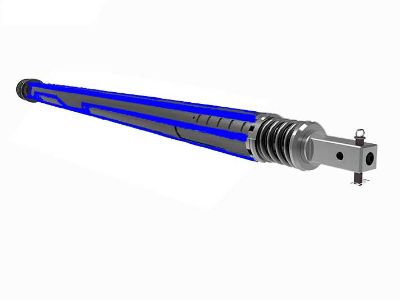

Roller Bits are specialized drilling tools that are essential to gas and petroleum natural extraction. In extracting these resources being natural cut through different stone formations at high temperatures and pressures. This procedure yields a total large amount of, heat and wear from the steel surfaces, that may sooner or later lead to failure or under-performance of the Roller Bits. The rotary drilling clear answer to this nagging problem is based on the lubricating oil system.

Advantages

The lubricating oil system offers advantages to Roller Bits that are numerous. Firstly, it reduces friction involving the different moving parts within the Bits, thus minimizing heat and wear. This not merely prolongs the lifespan of the Roller Bits but also helps to maintain their efficiency and efficiency. Additionally, the lubricating oil system helps to prevent dust and debris from clogging up the Bits, allowing for continuous drilling operations. Lastly, the oil system additionally assists to reduce steadily the likelihood of accidents occurring during drilling operations.

Innovation

Through the years, there were wide innovations ranging the look and technology of lubricating oil systems for Roller Bits. One of this latest innovations may be the development of synthetic lubricants. These lubricants are specially formulated to withstand extreme temperatures and pressures, reducing wear and maintaining effectiveness even yet in harsh surroundings. Additionally, the use of computer simulations and models has permitted for the optimization of oil cooling and flow within the Bits, resulting in improved drilling performance.

Safety

Safety is a critical issue any drilling task. Effective lubrication of Roller Bits is crucial in ensuring the safety of this drilling crew. The Roller Bits lubricating oil system helps to avoid wear and overheating of the Bits, minimizing the chances of sudden failure that will end in accidents. Proper maintenance and inspection linked to the lubrication system also assist to ensure its continuous function and associated with drilling operation.

Use

The use associated with the lubricating oil system in Roller Bits is relatively easy. Before using Roller Bits, make sure that the lubricant was filled. The total amount of shall rely on the type, size and conditions associated with drilling operation. It is important to monitor the oil level and occasionally add more lubricant when necessary. Additionally, through the drilling procedure, ensure that the oil system is functioning effectively.

Service

Regular maintenance and service are necessary for the proper event of lubrication system. The lubricating oil system in Roller Bits requires ensure inspection periodic it's functioning properly. Throughout the inspection, always check for any leaks, blockages or any other kinds of damage to the system. The device additionally requires regular cleaning make certain that no debris or particles clog up the oil stations. Its recommended that the lubrication system is serviced by a professional, experienced technician.

Quality

Lastly, the quality of this lubricating oil system is most critical. The Single Roller Bits product range of lubricant and system design must certanly be predicated on the specific wants conditions of the drilling operation. Quality lubricants ought to be able to withstand high conditions pressures, provide efficient lubrication, remain stable and non-corrosive. The lubrication system must certanly be created to also enable efficient flow cooling concerning the oil.